It sounds impossible, but using a series of precisely orchestrated light projections shined into a carefully engineered UV-polymer resin, Carbon can build parts that solidify as their build platform rises up from above the liquid plastic pool. Current polymer materials include polyurethane derivates, urethane methacrylate, cyanate ester, silicone, epoxy, and multiple proprietary blends.

However, what truly separates this process (Digital Light Synthesis™) from the processes of 3D printing competitors is that Carbon’s technique can print parts with microstructures that resemble those of injection-molded parts – a nearly unachievable feat for traditional layer-by-layer 3D printing approaches.

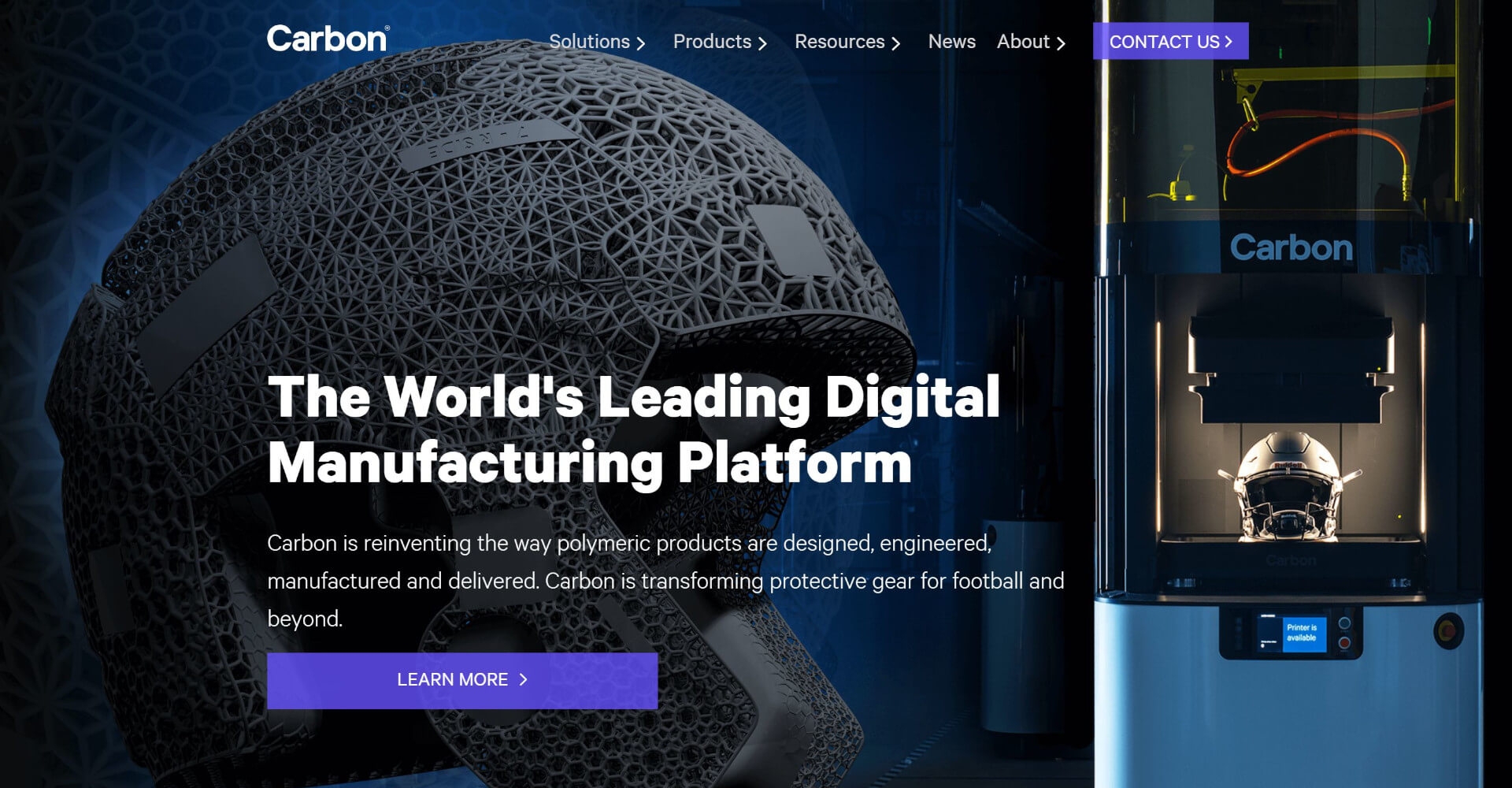

The company has been mass producing their commercial-grade M series entry level printers since 2016, and most recently, Carbon released their first L series printer – capable of creating multiple components simultaneously, and currently being utilized by adidas and Riddell for the production of millions of consumer-grade parts.

Carbon has come a long way since its inception in 2013, when co-founder Joseph M. DeSimone, PhD and 3-time elected national academies official, decided to start the company in an effort to marry “the intricacies of molecular science with hardware and software technologies to advance the 3D printing industry beyond basic prototyping to 3D manufacturing.”

Today, the company has raised a total of almost $700 million over 6 rounds of funding, and their most recent infusion of $260 million is helping Carbon pave the way for global expansion of its digital manufacturing platform.

When asked about his impression of Carbon, investor Greg Penner, founder and general partner of Madrone Capital Partners and Chairman of Walmart stated: “What impresses me about Carbon is their diversification across markets and industries. Through their partnerships with large-scale manufacturers in automotive, healthcare, and consumer goods, they are proving that, with their Digital Light Synthesis™ technology, additive manufacturing in larger scale production is becoming a reality across industry sectors. This is an inflection point for the company, and we’re proud to be able to contribute to Carbon’s future success.”