Browse

Nuclear Waste’s New Best Friend

Fix the waste and danger issues, and nuclear power is our most proven, cost-effective technology for satisfying the world’s growing energy demands.

3D Printing Water Filters

Higher throughput, more durability, and easier to manufacture than traditional filtration membranes.

Hardware Designed for Machine Learning

A 1M neuron neuromorphic chip means true AI vision processing may come sooner than we think.

Making the Best of Our Addiction to Plastic

Plastic is so abundant that companies are paid to collect and dispose of it. So much free material, why not turn it into something useful?

Re-Purposing Air Pollution

“Pollution is nothing but resources we are not harvesting. We allow them to disperse because we’ve been ignorant of their value.” – Buckminster Fuller

Changing Materials Instead of Manufacturing

Batteries just became way more efficient, and companies don’t even need to re-tool to make them.

Groundbreakingly Safe and Scalable Nuclear Power

These nuclear power modules rely on physics to power off and cool down – no electricity or operator action required.

Turning Food Waste into Electricity

What if instead of throwing out our food scraps, we used them to create heat and electricity?

Personalizing Nano Particles for Drug Delivery

Testing nano particle’s toxicity and drug delivery effectiveness, then custom manufacturing candidate particles for applications in targeted medicine therapies.

A Leap in Cell Imaging for Researchers

Readcoor uses a light-based imaging technique (FISSEQ) to map cells’ gene expression without destroying their spatial orientation – at 3000x the resolution of research standard technologies.

Get Paid for Your DNA, and Better The World Doing It

Nebula Genomics wants to sequence your DNA, and then help you get paid for it.

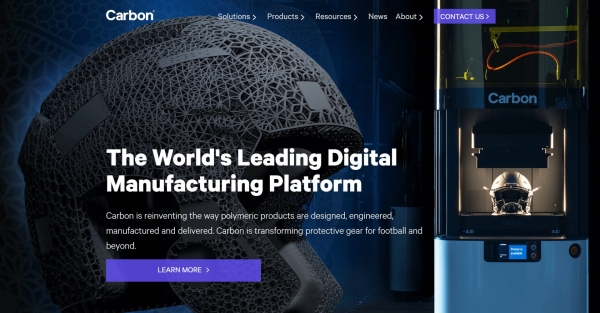

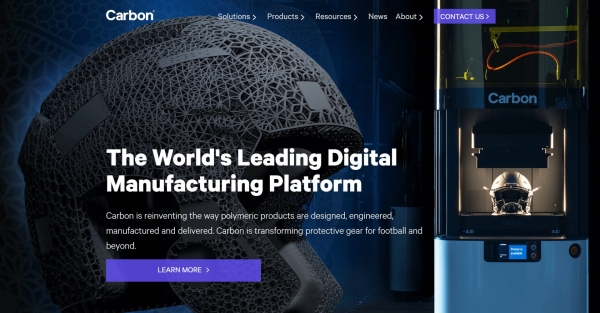

Pulling Solid Parts Out of Liquid Plastic

Carbon’s equipment can pull a production-grade 3D printed part out of a pool of liquid plastic.

Discovering Materials Using AI

Citrine Informatics is changing the culture around making new materials by integrating AI into the materials design process to drastically cut development time.

A Non-Invasive Brain Computer Interface

Imagine interacting with the digital world using only your thoughts – no surgery required.

Turning Your Favorite Clothes into "Smart" Wearables

Pireta can add conductive patterns directly onto fabric without changing the clothes’ performance – and they can do it at any stage in the manufacturing process.

Printing Metal at Production Speeds

Spee3D has created the world’s fastest metal 3D printer, capable of building production quality metal parts in literally minutes – as compared to 3D printing front-runners whose parts take hours to print.

Browse

Nuclear Waste’s New Best Friend

Fix the waste and danger issues, and nuclear power is our most proven, cost-effective technology for satisfying the world’s growing energy demands.

3D Printing Water Filters

Higher throughput, more durability, and easier to manufacture than traditional filtration membranes.

Hardware Designed for Machine Learning

A 1M neuron neuromorphic chip means true AI vision processing may come sooner than we think.

Making the Best of Our Addiction to Plastic

Plastic is so abundant that companies are paid to collect and dispose of it. So much free material, why not turn it into something useful?

Re-Purposing Air Pollution

“Pollution is nothing but resources we are not harvesting. We allow them to disperse because we’ve been ignorant of their value.” – Buckminster Fuller

Changing Materials Instead of Manufacturing

Batteries just became way more efficient, and companies don’t even need to re-tool to make them.

Groundbreakingly Safe and Scalable Nuclear Power

These nuclear power modules rely on physics to power off and cool down – no electricity or operator action required.

Turning Food Waste into Electricity

What if instead of throwing out our food scraps, we used them to create heat and electricity?

Personalizing Nano Particles for Drug Delivery

Testing nano particle’s toxicity and drug delivery effectiveness, then custom manufacturing candidate particles for applications in targeted medicine therapies.

A Leap in Cell Imaging for Researchers

Readcoor uses a light-based imaging technique (FISSEQ) to map cells’ gene expression without destroying their spatial orientation – at 3000x the resolution of research standard technologies.

Get Paid for Your DNA, and Better The World Doing It

Nebula Genomics wants to sequence your DNA, and then help you get paid for it.

Pulling Solid Parts Out of Liquid Plastic

Carbon’s equipment can pull a production-grade 3D printed part out of a pool of liquid plastic.

Discovering Materials Using AI

Citrine Informatics is changing the culture around making new materials by integrating AI into the materials design process to drastically cut development time.

A Non-Invasive Brain Computer Interface

Imagine interacting with the digital world using only your thoughts – no surgery required.

Turning Your Favorite Clothes into "Smart" Wearables

Pireta can add conductive patterns directly onto fabric without changing the clothes’ performance – and they can do it at any stage in the manufacturing process.

Printing Metal at Production Speeds

Spee3D has created the world’s fastest metal 3D printer, capable of building production quality metal parts in literally minutes – as compared to 3D printing front-runners whose parts take hours to print.